X-ray and optics

X-ray and optics

X-ray separator

To sort mechanical pieces through the atomic analysis of the material. The integrated software processes the data received through scanning and, depending on the selected program, decides whether or not to activate the pneumatic sorting device.

The X-ray separator of Panizzolo Recycling Systems is developed jointly with leader companies in the sector, considered top quality on an international level. Structural steelwork and interconnection software with the entire plant are developed directly by Panizzolo, so as to streamline and speed up periodic inspections and maintenance. The coupled vibrating table allows to evenly distribute the material on the belt and improves its exposure to the x-rays.

Complement: compressed air and cleaning kit

The kit is installed on a portable base. It includes a compressor and specific tanks with cleaning and filtering systems. Specifically designed and dimensioned, it sends a constant clean air flow to the sorting device. Includes connection pipes and fittings.

Optical Sorter

Sorting and separation system of granulated metal by means of RBG trichromatic cameras. It recognises the object by colour and size features. Optical resolution 0.1 mm. Supplied complete with support structure and electric control panel.

The optical sorter is developed in collaboration with hi-tech companies working in the sector. Structural steelwork and interconnection software with the entire plant are developed directly by Panizzolo, so as to streamline and speed up periodic inspections and maintenance.

Complement: loading feeder belt

Includes a hopper that acts as a tank and an adjustable sliding belt. Complete with electrical connections to the plant’s management software.

Complement: compressed air kit

Specifically sized for the correct operation of the optical sorter. Includes connection pipes and fittings.

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Sieves

Sieves

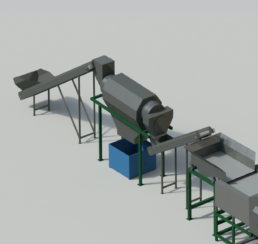

Dynamic Shake

The materials resulting from fine grinding of Flex Mega, Mobile and Stationary Refine series hammer mills are treated with vibrating, rotating screens. The metal separators of the Dynamic Shake series, in particular, are plants designed to separate metal granules from inert powders.

Optimal separation of the non-magnetic material from the magnetic one is obtained thanks to the combined use of a special step-shaped surface and the particular separation belt structure. This accessory, like other Panizzolo Recycling integrated systems, has been designed to maximise the recovery of secondary raw materials and minimise final waste.

Comb vibrating table

Complete with interchangeable combs and module with magnetic drum. Mainly used in the electric motors processing cycle, it performs a primary sorting by size.

Rotary Sieve

Available in different sizes and models according to the processing cycle it is inserted in. It has an interchangeable calendered perforated mesh inside. The combination between rotary and tilting movement separates the material into two sizes: undersieve and oversieve. Supplied to complete the Panizzolo processing cycles, they are available in different models and sizes.

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Eddy current

Eddy current

The bulky waste sorting systems for non-ferrous and inert materials of the Eddy Current series ensure thorough sorting of processed materials – a key step to properly refine metal scrap. Thanks to an eddy current system, these plants perfectly sort out non-ferrous metals such as aluminium, copper and stainless steel from heavy inert materials such as plastic, rubber and wood. A high efficiency version is also available for the recovery of stainless steel and non-ferrous metal granules.

Panizzolo eddy current sorting systems are developed in collaboration with leader companies in the sector, considered top quality on an international level.

The machinery is supplied complete with support structure and electric panel with control management software. Steelwork and software designed directly by Panizzolo, so as to streamline and speed up periodic inspections and maintenance. The vibrating table coupled to eddy current allows to evenly distribute the material on the belt and improves its exposure to the magnetic poles.

Models table:

| model | Standard operating range | Indicative production: up to….ton/h | ||

| Profile aluminium | Mixed aluminium | |||

|

width 1000 |

ECP-BV 1000 | Medium-Fine | 4 | — |

| ECP-V 1000 | Medium | 6 | — | |

| ECP-ES 1000 | Medium | 6 | — | |

| ECP-V 1000 | Medium-Fine | 5 | 6 | |

| ECP-E 1000 | Medium | 9 | 11 | |

| ECP-S 1000 | Heavy | 9 | 11 | |

| Width 1500 | ECP-V 1500 | Medium | 9 | — |

| ECP-ES 1500 | Medium | 9 | — | |

| ECP-E 1500 | Medium | 12 | 14 | |

| ECP-V 1500 | Medium-Light | 8 | 10 | |

| ECP-S 1500 | Heavy | 12 | 14 | |

| Width 2000 | ECP-V 2000 | Medium-Fine | 12 | — |

| ECP-S 2000 | Heavy | 15 | 18 | |

Complement: special drums and belts

The specific upgrades are developed directly by Panizzolo. They can be supplied according to the type of material and production cycle.

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

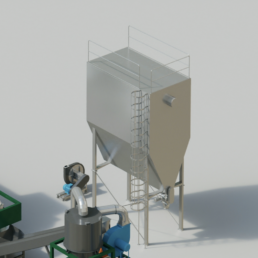

Air handling filter

Air handling filter

Supplied to complete Panizzolo systems, the air flow rate, fans and extraction ducts are calibrated by the technical department according to the production layout. The bag filter performs dry extraction and filtering of the dust produced during the waste processing cycle.

The operating and monitoring controls are located in the middle of the plant’s control panel, greatly simplifying control, management and maintenance.

Complement: air compressor with structure

Pneumatic system for cleaning bag filters. Complete with structure, nozzles and connection pipes.

Complement: spark detection system

Optical sensor for the fire protection of the filter. Complete with valves and electrical connections.

Complement: Special alloys for wear-causing dusts

If the processing cycle includes extraction of wear-causing dusts (with presence of glass, cement, etc.), Panizzolo allows you to install leadscrew nuts and impellers in specifically designed alloys.

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Air density separators

Air density separators

The Zig-Zag air density separators are designed to separate bulky metal pieces from light inert materials such as fabrics and plastics. Processing is performed by means of air jets which ensure perfect cleaning and recovery of the output materials. The Zig-Zag range of metal air density separators is available in various models, which can be selected according to the processing flow, the outputs of the grinding plant and the sorting quality to be obtained.

Models table:

| Models | Electric power |

| ZZ 5000 | 9 kW |

| ZZ 7500 | 13 kW |

| ZZ 10000 | 22 kW |

| ZZ 15500 | 31 kW |

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Soundproofing cabin

Soundproofing cabin

Soundproofing specifically dimensioned to contain and reduce the noise of the Panizzolo hammer mill. The walls are made of self-bearing panelling, containing specific water repellent soundproofing material. It has a manual side sliding door providing full access to the hammer mill. Supplied complete with ladder, access door, up to two compartments for the extraction of processed material, lighting and safety circuit.

Complement: Customised emblem

With no additional costs, you may customise two emblems with your company logo.

Complement: column crane with folding boom

For outdoors or indoors depending on the production area. Structurally suitable according to the hammer mill model.

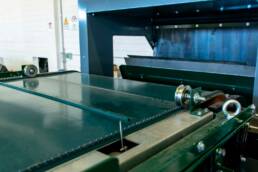

Cabin for manual sorting

Specific soundproof cabin for manual sorting, supplied in different models and completing Panizzolo recycling solutions. Dimensions and compliments change according to the processing logic and production area. Supplied already with a suitable conveyor belt.

The standard composition of a Panizzolo cabin includes insulated walls, electric and lighting circuit, air circulation, operator workstation, air conditioning/heating systems and other accessories that guarantee the complete livability of personnel working inside.

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.