Recyclingof mixed metals

Extremely important for industry, metal is the most requested raw material, but also the most expensive. This is why recycling these materials has undergone an exponential increase with the continual improvement of the recovery process. The real challenge is implementing a quality recovery, with a profitable economical and eco-friendly return.

Efficient treatmentsfor high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

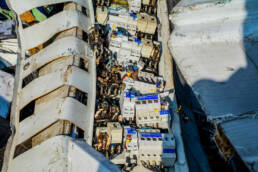

Mixed metals are well represented by complex waste such as a plant’s electrical switchgear. You can find the metal enclosure as well as many components such as switches, fuses and cables, that need to be thoroughly divided into ferrous and non-ferrous fractions or other. Adequately breaking down and treating mixed metals to then put a high quality recycled metal back on the market is an economical and eco-friendly interest.

The recovery process of mixed metal scrap consists of sequential shredding, volumetric reduction, grinding, sorting and separation stages of the output granules.

Last generation technologies applied to our metal treatment plants allow to fully recover secondary raw materials – up to the smallest ferrous fractions and above all metals such as aluminium, copper and brass – in full compliance with standards against environmental pollution. We know the value of an efficient cycle both from a production and energy consumption standpoint since we are direct users of machinery and of mixed metal recycling plants.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.