Electric motors

Recycle

electric motors

The electric motor is definitely the scrap with the highest concentration of iron, copper, brass and aluminium when it comes to metal waste.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

There are no doubts about possibility of processing electric motors since up to 98% of its overall weight can be recovered, transforming it into secondary raw material. The market is extremely open at this time: construction, transport vehicles and technology greatly need for these metals. From a processing standpoint, the electric motor is not an “easy” waste due to its highly wear-causing features that puts pressure on the rotors, grilles and blades of the recovery plants. At the same time this scrap features a large range of different sizes, from an overall weight ranging from 10 kg to 40 kg and the processing cycle changes based on the size. Companies processing this product must definitely pay the utmost attention to the solidity of their breakup and grinding machinery. At Panizzolo, as direct users, we know only too well the issues related to wear and strong stress that the components, welds and steelwork are subject to.

This is why our hammers and armours are made in special anti-wear castings specifically designed jointly with the University of Padua – for the processing of bulky waste. The sorting of the outfeed granule is just as important. General sorting is not acceptable for foundries and steel mills as it causes problems during the various material casting stages, such as what occurs in foundries when copper residues lead to important defects in iron castings. This is why the Panizzolo refining systems have an advanced separation stage, to complete the grinding cycle, achieving a high quality final result In this regard, the latest technological updates have led us to insert a high precision optical sorter.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Weee

Recycle

electronic waste WEEE

Electronic and electrical waste represent a great challenge in recent years. Continuously growing, they become an important product for metal processing companies. Panizzolo plants can recover the steel, iron, copper, brass, aluminium and printed circuit metal fractions.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

Waste electric and electronic equipment, abbreviated WEEE, is a waste growing at a high rate which was processed inappropriately in the past. In recent years, industrial economies and a technology-dependent lifestyle have brought about a great accumulation of this type of waste and the need for a specific treatment aimed at recovering the valuable materials present in electronics and microelectronics. Different types of processing cycles are expected depending on the type of WEEE – mainly divisible between household, commercial and technological – going from the recovery of the electric motor and ferrous

components to the valorisation of those commonly known as “rare earth elements”. Panizzolo plants join in processes aimed at recovering steel, brass, iron, aluminium, plastic and copper. These metals are found in power supply units, electric cables and various types of components and require a preliminary mechanical sorting, subsequent grinding and quality sorting.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Suw

Treatment of urban waste

SUW - MSW

Solid Urban Waste or Municipal Solid Waste makes up a high percentage of the household and commercial waste produced. The heterogeneous set of this waste is generically called “dry” and mainly consists of various types of plastic mixed with small percentages of metals.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

The treatment of solid urban waste includes an initial stage consisting of dividing solely plastic materials from components containing metal. Composite waste follows a primary grinding route, magnetic sorting and density sorting, so as to extract iron, aluminium, copper and brass. The non-metal residues left over can again be treated with specific cycles or handed over to the incinerator.

Here too, like in other recycling processes, sorting distinguishes between general production and quality production which aims at maximising the yield of waste in terms of quantity and quality of the extracted secondary raw material.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Tins

Treatment of aluminium cans

and recycling of waste tins

Household and industrial consumption is witnessing a great increase in long-life foods, which need to be packed hermetically in composite paper and plastic containers or in metal packaging. The recycling sector is ever more focusing on the treatment of aluminium cans and metal tins in general.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

Tins include metal boxes and cans, but also glass bottle caps, waste that features a very high concentration of metal and only 1% of residual materials. Among the shelf-life solutions proposed by large-scale retailers, the tin can remains the perfectly recyclable enclosure providing an ideal ratio between raw material obtained and energy used. These materials can practically be recovered without end and, respect to the primary production of new containers, recycling significantly reduces energy consumption and CO2 emissions with great advantages on an ecological and economical level.

The recycling of cans and jars allows to recover metals such as steel, tin and aluminium. During the recovery stage, these metals are ground to clean them from damp, paper and plastic labels and paints, thus obtaining a secondary raw material in compliance with current standards. The metal obtained is recovered for steel mills and needs careful sorting to eliminate all the impurities present and to achieve an increase in density.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Metal scrap

Recycle waste

from metal scrap

How do you treat metal scrap? Following changes on the market in recent years and in compliance with new European standards, companies are ever more encouraged to perform End-of-Waste treatments, to totally recover metals and transform them into secondary raw material.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

Metal scrap has always been a waste of great interest due to its high concentration of metal – in some cases reaching 90% of its overall weight. This led in the past to many companies founding their business on the marketing of metal scrap. In recent years, the recycling of this type of material is even more quoted due to the increase in prices of raw materials and a progressive conversion of these businesses to a complete treatment process. In fact recovery represents an important occasion from an environmental standpoint and a more eco-friendly solution than the brand-new production of metals, and this is not all! The conversion from only marketing to a complete metal treatment cycle entails a variety of economical advantages and the possibility of opening new perspectives for one’s business and new concrete trade opportunities.

The exponential improvement in recycling processes and innovative grinding and sorting technologies allow our metal transformation plants to return a homogeneous material with a high specific weight, ideal to be put back on the market. It is fundamental that they comply with all of the conditions set forth by EU standards to become secondary raw material and no longer fall under the waste category. The high quality of our outputs is guaranteed and is ideal for the direct sale of iron, copper, brass, steel and aluminium to foundries and steel mills.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Mixed metals

Recycling

of mixed metals

Extremely important for industry, metal is the most requested raw material, but also the most expensive. This is why recycling these materials has undergone an exponential increase with the continual improvement of the recovery process. The real challenge is implementing a quality recovery, with a profitable economical and eco-friendly return.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

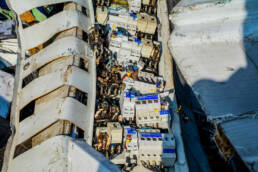

Mixed metals are well represented by complex waste such as a plant’s electrical switchgear. You can find the metal enclosure as well as many components such as switches, fuses and cables, that need to be thoroughly divided into ferrous and non-ferrous fractions or other. Adequately breaking down and treating mixed metals to then put a high quality recycled metal back on the market is an economical and eco-friendly interest.

The recovery process of mixed metal scrap consists of sequential shredding, volumetric reduction, grinding, sorting and separation stages of the output granules.

Last generation technologies applied to our metal treatment plants allow to fully recover secondary raw materials – up to the smallest ferrous fractions and above all metals such as aluminium, copper and brass – in full compliance with standards against environmental pollution. We know the value of an efficient cycle both from a production and energy consumption standpoint since we are direct users of machinery and of mixed metal recycling plants.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Aluminium

Recycling

aluminium

The market demands ever more lightweight and efficient alloys, making aluminium the metal of the future par excellence. Its recovery is an important from an economical standpoint.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

An ever more large variety of objects, products and components are made in aluminium or in its primary and secondary alloys. Its features make this metal essential both in the construction of many common objects (bicycles, windows, coffee makers, etc.) and for technologically advanced and complex components (trains, cars, computers, aircraft and still more). As it does not exist in nature, aluminium has been recycled since 1900. Particularly in today’s circular economy it covers an important role. The recycling of aluminium, whether it be profile or casing, means dividing it from all the components with which it is assembled. One of the most common examples is the recycling of aluminium window frames which include screws, glass, handles and plastic with thermal functions.

Grinding operations can completely separate the additional materials so as to preserve the primary alloy aluminium, an ideal solution with respect to a process that entails casting that could create less valuable secondary alloys. X-ray sorting devices are used in our recycling plants for better selection of the aluminium alloy quality. They separate primary aluminium from secondary aluminium, an essential distinction for better yield during casting at the foundry.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Refining

Refining of fluff

and mixed metals waste

Every year, ever more tons of waste are exported or sent to a landfill, despite containing high percentages of metal such as copper, brass and aluminium. They come from several processing cycles and the main difficulty encountered is the high amount of wear-causing inerts inside of them.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

The Panizzolo refining plant uses patented hammer mills of the series RAF-M and RAF-F. These are efficient and highly productive systems capable of simultaneously processing wear-causing steel and inerts, both during the grinding and granulation stage. The processed metal scrap can cause significant wear, thus undermining the actual yield of processing over time. On the other hand Panizzolo refining plants are specifically designed for even wear of the individual components, so as to avoid breakage or sudden drops in production. Furthermore use of special castings makes the hammers and armours more durable. The main type of waste treated by the Panizzolo refining plant includes:

- Copper from electric motor grinding with presence of iron, plastic, stainless steel, etc.

- Fluff from: Cars, Mixed metals, WEEE grinding

- Cables contaminated by stainless steel, brass, iron, ACSR cables

- Inert containing metals

- Alucubond, Aluminium caps, etc...

- Other mixed fluff waste resulting from pre-treatments and containing a mixture of copper, aluminium, steel, glass and cement dust.

At the end of the treatment cycle, almost all non-marketable byproducts are eliminated, retrieving only the clean metal granules, classifiable as secondary raw material.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Slag processing

Slag processing

and recovery of industrial waste

From special waste to resource: the recovery of industrial waste, and in particular of slag, allows to exploit metals and construction materials.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

If steel mill slag was considered special waste up to a few years ago, today this industrial byproduct is a valid source of recovery of metal and non-metal material. There is a growing demand for aggregates in the construction sector, while quarries are diminishing. Following this trend, the slag from special waste has been reclassified as recoverable waste.

This allowed us to discover that when properly treated, slag possesses better physical and mechanical properties than other materials and inerts and is rich in metallic residues. This waste can therefore recover its direct use without being sent to a landfill. It can be used in a wide range of options such as materials for construction and other industrial sectors.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Paper mill pulper

Recovery of

paper mill pulper

In the circular economy, paper is one of the most recycled materials. The recovery process gives way to a buildup of waste material, called paper mill pulper, consisting of plastic, fibres, fabric filaments, metal and which require a specific recycling process.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

Paper mill pulper is the waste produced by the paper industry in the waste paper recycling . After recovery of the cellulose fibres, a non-recyclable mixed material mixture remains which used to be sent to a landfill with high waste disposal costs. Today it can undergo a recovery process, thus reducing the waste sent to a landfill and recovering still reusable materials.

Thanks to ever more specific and advanced technologies, paper mill waste treatment cycles can be implemented. These operations have reasonable costs and are performed in automated mode, again recovering the metals contained and reintroducing them into the production cycle.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.