End-of-life vehicles

Treatment and recovery

of end-of-life vehicles

Among special waste, end-of-life vehicles represent an important source of secondary raw materials. However their complex composition makes their treatment difficult and long in a profitable way.

Efficient treatments

for high quality results

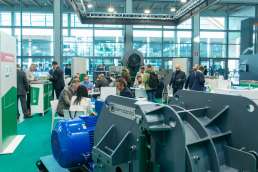

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

At the end of their life cycle, vehicles undergo a sorting process to recover the components that still work and to send unusable components to proper waste disposal. Many of these operations are still carried out by means of laborious manual sorting jobs which slow down the end-of-life vehicle recovery process and nullify its profitability. As far as this is concerned, latest statistics on the correct disposal of automotive waste point out that the amount of car disposal facilities is dropping and that Italy is below the required European standards (read article). Like in other situations, the new recycling technologies can represent an important solution. Automation of the recycling operations reduces manual labour and processing times and allows for the proper sorting of all of the components.

This way metals, fabrics, plastic and rubber are divided correctly and quickly, leading to significant gains in profit. Automotive shredder residue (ASR) represents a big problem in the sector. It consists of glass, fabric fibre, rubber, plastic, and various types of filth and still feature a considerable percentage of metals such as iron, steel, copper and aluminium that need to be brought for recovery. This fluff can be introduced into the Panizzolo refining plant, performing an End-of-Waste treatment cycle and recovering all the metal components.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.

Car engines

Recovering metals

from car engines

How should car engines be processed? Following changes on the market, companies are ever more encouraged to implement treatments for efficient recovery and sorting of secondary raw material.

Efficient treatments

for high quality results

Panizzolo plants are valued for their production performance, low consumption and management costs, and their ease of use. We stand out for our strong experience as direct users of processing systems and, exploiting this know-how, we study all the new solutions focusing on the customer and on the success of their investment.

Car engines can only be sent to the treatment cycle after a thorough reclaiming process, namely elimination of internal oil and liquids. They have a high concentration of metal, including aluminium and iron, depending on whether it is car or truck engine. Again depending on the model we can find: the electric starter motor, brass for the transmission mechanism and inerts such as plastic and rubber. In fact recovery represents an important occasion from an environmental standpoint and a more eco-friendly solution than the brand-new production of metals, and this is not all! The conversion from only marketing to a complete metal treatment cycle entails a variety of economical advantages and the possibility of opening new perspectives for one’s business and new concrete trade opportunities.

Thanks to the innovative grinding and sorting technologies of our plants, the metals in car engines can be thoroughly recovered and reintroduced in the production cycle. The high quality of our outputs is guaranteed and is ideal for the direct sale of iron, copper, brass, steel and aluminium to foundries and steel mills.

Find out more about all our recycling solutions!

Video Gallery Input and Output

What is your treatment requirement?

We listen to your needs and can supply you with the best technologies to meet your business goals.

The processing cycles are designed to maximise production activities, to be able to attain full recovery of secondary raw materials and to reintroduce them directly into the economic cycle.

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.