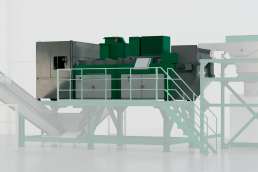

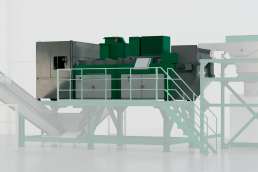

Mega stationary hammer millsSeries 7

Designed for the grinding of the heaviest scrap, the Mega series hammer mills combine robust construction and patented technologies to ensure profitable and reliable production cycles over the long term.

Key strengths

Grinding logic

The structure of the mill is designed to prevent the ejection of material from the inlet while wear is limited to armours, grilles and hammers. These items are manufactured with the best steels and castings for gradual wear and keeping the quality of the ground scrap constant.

Low energy costs

The hammer mill maximises the ratio between energy consumption and hourly productivity. The line includes models from 355 kW to 450 kW, with production performance from 25 ton/h to 35 ton/h depending on the machinery.

Low management costs

The machinery is designed to minimise production downtime and the number of operators involved in the operation. The software autonomously monitors and adjusts the treatment, so that personnel do not need to be constantly near the plant.

Rotor and hammers

The rotors facilitate the shredding of scrap by absorbing stresses without causing structural repercussions over time. All components are designed in-house, eliminating the most common weak points. The hammers are installed with 360-degree free rotation and are made of a special alloy developed in collaboration with the University of Padua. They are designed to ensure excellent crushing capacity while resisting deformation, breakage, or cracks over the long term.

Easy maintenance

These periodical operations require an essential number of operators, without the need for special equipment or highly professional competences. The rotor can turn all the way thanks to the built-in double sheave. Controls and greasing are designed to be simple and intuitive.

Accessories

X-ray and optics

For separating mechanical fractions through atomic material analysis. Equipped with integrated software.

Eddy current

For precise separation of non-ferrous metals, thanks to an eddy current system.

Air treatment filter

For suction and dry filtering of dust generated during processing, with centralized control from the plant’s main panel.

Air densimetric separators

For separating heavy metal fractions from inert materials, using air jets that ensure perfectly clean output material.

Soundproof cabins

For reducing hammer mill noise, with self-supporting panels made of water-repellent sound-absorbing material.

Conveyor belts

For transporting scrap and optimizing material flow within the plant, available in different models and sizes.

X-ray and optics

For separating mechanical fractions through atomic material analysis. Equipped with integrated software.

Eddy current

For precise separation of non-ferrous metals, thanks to an eddy current system.

Air treatment filter

For suction and dry filtering of dust generated during processing, with centralized control from the plant’s main panel.

Air densimetric separators

For separating heavy metal fractions from inert materials, using air jets that ensure perfectly clean output material.

Soundproof cabins

For reducing hammer mill noise, with self-supporting panels made of water-repellent sound-absorbing material.

Conveyor belts

For transporting scrap and optimizing material flow within the plant, available in different models and sizes.

Grinding patents

A common characteristic of Panizzolo hammer mills, the interchangeable cradle is a significant plus in the grinding of metal scrap.

Want to discover all the Panizzolo machines?

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.