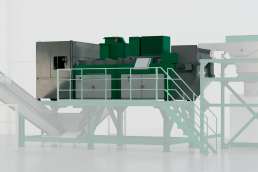

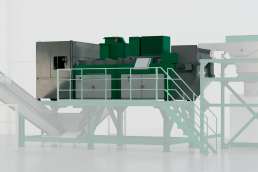

Mobile hammer mills

The hammer mills of the Flex Mobile series are transportable machines designed for grinding metal scrap. Compact, easy to maintain and supplied turnkey, they deliver high performance and maximum flexibility.

Key strengths

Transport and installation

The special frame makes loading and unloading of the machinery simple, while the compact structure avoids needing to use exceptional transport on road. The Flex Mobile series is supplied pre-assembled, allowing for quick installation.

Low energy costs

The hammer mill maximises the ratio between energy consumption and hourly productivity. The line includes models from 90 kW to 315 kW, with production performance from 3 ton/h to 13 ton/h depending on the machinery.

Easy-to-use

The machines are designed to minimize production downtime and the number of operators required for operation. Maintenance is intended to be simple and fast, thanks to full access to the grinding chamber, where interventions can be effectively carried out on the cradle, rotor, grids, hammers and armours.

Low sound emissions

The outside of the Flex Mobile hammer mills are covered with soundproofing and water repellent panelling, to greatly reduce noise and protect against atmospheric agents.

Treatment flexibility

Thanks to the patented cradle built into the hammer mill, the machinery stands out for high flexibility in processing scrap.

The models of the Flex Mobile series

Accessories

X-ray and optics

For separating mechanical fractions through atomic material analysis. Equipped with integrated software.

Eddy current

For precise separation of non-ferrous metals, thanks to an eddy current system.

Air treatment filter

For suction and dry filtering of dust generated during processing, with centralized control from the plant’s main panel.

Air densimetric separators

For separating heavy metal fractions from inert materials, using air jets that ensure perfectly clean output material.

Conveyor belts

For transporting scrap and optimizing material flow within the plant, available in different models and sizes.

X-ray and optics

For separating mechanical fractions through atomic material analysis. Equipped with integrated software.

Eddy current

For precise separation of non-ferrous metals, thanks to an eddy current system.

Air treatment filter

For suction and dry filtering of dust generated during processing, with centralized control from the plant’s main panel.

Air densimetric separators

For separating heavy metal fractions from inert materials, using air jets that ensure perfectly clean output material.

Conveyor belts

For transporting scrap and optimizing material flow within the plant, available in different models and sizes.

Grinding patents

A common characteristic of Panizzolo hammer mills, the interchangeable cradle is a significant plus in the grinding of metal scrap.

Want to discover all the Panizzolo machines?

Towards the futureof the sector

It’s good to keep up-to-date on a market always on the move.

Follow the news in the sector and the Panizzolo columns.